6 Sustainable Packaging Switches: A Guide for Eco-Conscious Businesses

In a world where customers are increasingly worried about climate change and the environment, businesses are under growing pressure to make sustainabl…

Macfarlane Packaging provides protective packaging products and services to businesses throughout the UK, Ireland and Continental Europe

In a world where customers are increasingly worried about climate change and the environment, businesses are under growing pressure to make sustainabl…

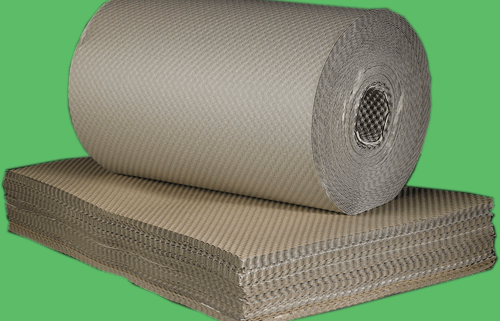

Most people know what cardboard, stretch wrap, polybags and other common forms of packaging look and feel like (and what they are typically used for)….

Manufacturing supply chains can range in size and complexity, often spanning continents and many businesses. But regardless of their setup, packaging,…

90% of your packaging costs could be hiding behind the unit price you pay. Macfarlane Packaging can help you identify, reduce and even eliminate these costs.

We can help your business be more sustainable with eco-friendly packaging solutions and expertise that can reduce CO2 from your supply chain, reduce waste and use less material.

The right packaging can deliver a memorable unboxing experience for your customers. At Macfarlane Packaging we can help you deliver a memorable unboxing experience that protects your products and your brand.

Macfarlane Packaging, the UK’s leading distributor of protective packaging, announces today (18 March) a new automation distributor agreement with U…

Macfarlane Group PLC is pleased to announce the acquisition of Allpack Packaging Supplies Limited. This earnings-enhancing acquisition further progr…

ANNUAL RESULTS 2023 Group profit before tax ahead of previous year FINANCIAL HIGHLIGHTS 2023 £000 2022 £000 Increase/ % (Decrease) £000…

And not just the cost of the packaging itself, Macfarlane Packaging can consider all the costs associated with your packaging operation.

Macfarlane Packaging can also help you to reduce the environmental impact of your packaging operation while giving your customers a great experience of your brand.

Whether you want to buy packaging materials now, ask for advice about custom packaging or transform your entire packing operation, our experts are on hand.

Macfarlane Packaging can support you through our extensive national branch network, European operations and state-of-the-art Innovation Lab. With thousands of packaging products at hand and ground breaking tools like our Packaging Optimiser, you can be confident that whatever your packaging challenge, Macfarlane Packaging has the solution.

How can we help?